For electricians working on either residential or commercial projects, safety is key in everything you do. From cutting electrical wires to repairing electrical systems, there’s a lot of danger to life when you’re an electrician, which means following the process to the letter is crucial for your well-being and the safety of others. It’s also to remember and follow a good and trusted electrical guide.

With that being said, here are the steps to take when you’re looking to cut electrical wires safely for both residential and commercial projects.

Inspecting the Electrical Setup

Before you begin, you’ll want to conduct a thorough visual inspection of the area and the specific wiring you’re looking to cut, and what you’ll want to avoid.

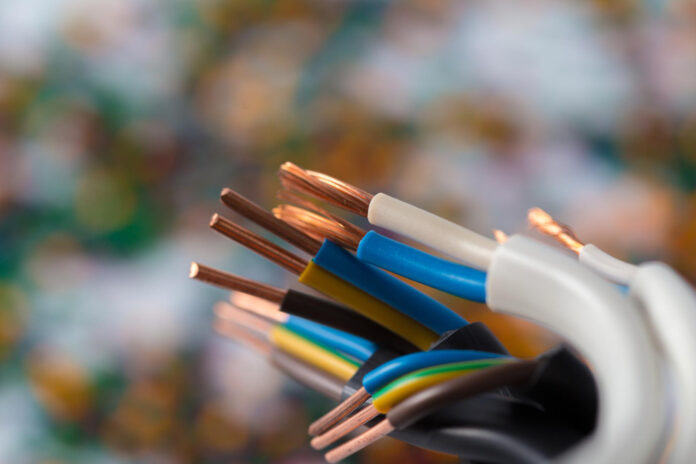

Determining the wire types is also key, whether it’s copper or aluminum, and their purpose, before proceeding. It’s useful at this point to check for any damage, looking for signs of overheating, frayed insulation, or corrosion on wires.

For wall and ceiling projects, it’s beneficial to use a cable detector in order to identify buried services that you can’t see and therefore could be a problem or risk.

Finally, make sure you assess the environment and ensure that the workspace is dry and therefore free of flammable gases or conductive dust.

Choosing the Right Tools

The tools of the trade are essential for any electrician, and making sure you have all the right cutters and insulated tools is key. You must be careful with your tools and equipment, making sure to keep them in good condition at all times and to check for any faults before using them.

Select your tools rated for the specific gauge and the type of wire being cut. Recommended tools for any electrician include the following:

- Lineman’s pliers – The safest of choices for general electrical work, from cutting to twisting and gripping.

- Insulated tools – Make sure to use insulated tools that provide an extra layer of protection.

- Diagonal cutters – Ideal for soft copper wires and small-gauge cuts being made.

- Cable cutters – Helpful for large-diameter or use on multi-conductor cables. These help to avoid crushing the internal conductors.

Preparing for the Cutting Process

It’s important to prepare for the cutting process instead of just going straight in. Preparation should focus on de-energizing the circuit so that it protects you and any workers. This is done by switching off the corresponding breaker located at the panel.

You’ll then want to apply a physical lock to the breaker to secure isolation and prevent accidental re-energization by others. A warning tag is useful to add to indicate you’re working on the circuit.

Verify the power is off by using a non-contact voltage tester on the wire itself to ensure no current is flowing. Finally, make sure to wear safety glasses as this helps protect you against any flying fragments. Insulated gloves should be used at this point, too.

Cutting the Electrical Wires

For a clean and safe cut, these top tips will help ensure you do so every time.

- Hold it steady – Grip the wire with one hand and tool in your dominant hand.

- Position the tool – Place the wire at a 90-degree angle to the jaws of the tool and make sure it’s centered before cutting.

- Apply pressure – Be sure to squeeze the handles evenly and apply steady pressure. For thicker wires, you may need two hands to cut them.

- Cut one at a time – Don’t cut multiple wires simultaneously, as this can cause a dangerous ground fault or even an explosion. Instead, cut them one at a time.

Ensuring Safety Measures

It’s important to ensure mandatory safety measures are in place at all times. From de-energizing the circuit to personal protective equipment.

Safety should always be at the forefront of everything you do, so make sure to remind yourself of the best practices when it comes to safety as an electrician.

It’s always helpful to check the workspace, inspect your tools, and cap all copper wire ends with wire nuts to prevent future hazards from occurring.

Handling the Cut Wires

As mentioned above, you shouldn’t be leaving raw wire ends exposed. Whether that’s in a wall or a ceiling.

Make sure to trim the edges with wire strippers to trim any sharp points or rough edges. Cap the ends immediately as mentioned and place the capped wires inside a junction box, covering it with a blank wall plate to maintain safety codes at all times.

Professional Assistance and Tips

For anyone who might be concerned about their electrics, consulting a licensed electrician is key. As the electrician, if you’re unsure of anything to do with the project, then involving another electrician, perhaps with more experience and knowledge, is worth doing in some scenarios.